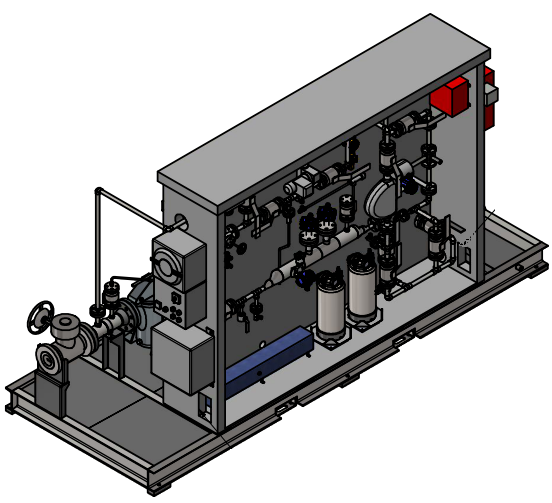

Trimet-JET-MIX POWER MIX SAMPLING SYSTEM SKIDS

JET MIX

Depending upon the process conditions, inline mixing is commonly required for large pipelines in order to create a homogeneous flow. Traditionally, static mixing devices consisting of a series of baffles or metal plates are installed in the main pipeline and are used to create enough turbulence to get a properly mixed flow. The energy needed for mixing comes from a loss in pressure as fluids flow through the static mixer. With this said, operators find this a less attractive solution because a loss in pressure would mean less throughput. Furthermore, static mixers are designed to operate with a certain turndown ratio, providing operators with inaccurate sampling results at the start and end of the batch. The patented Jetmix technology provides the perfect solution for such applications, with nihil pressure drop in the main pipeline and a homogenous flow independent upon the flowrate. The JET MIX is an efficient design, consisting of an external pump, mixing nozzle, and a take-off quill, as drawn in the picture below. A part of the main stream is pumped around and re-injected into the mainstream using the efficient and patented nozzle mixing device. In the created loop, where the innovative and sustainable cell sampler is located, accurate and representative grabs are taken and transferred to receiver cans. Furthermore, the e-JetmixTM nozzle and quill can be retracted for pigging purposes.